Quantity: 300 pieces

Size:2.0 x 1.2 (mm) / 0.08 x 0.05 (inch)

Emitting Color: White (6000K-9000K)

Luminous Intensity: 180-210mcd

Viewing Angle: 120 Degree

Forward Voltage / Current: 3V-3.2V | 20mA

Polarity: Refer to the Arrow on the Reverse Side

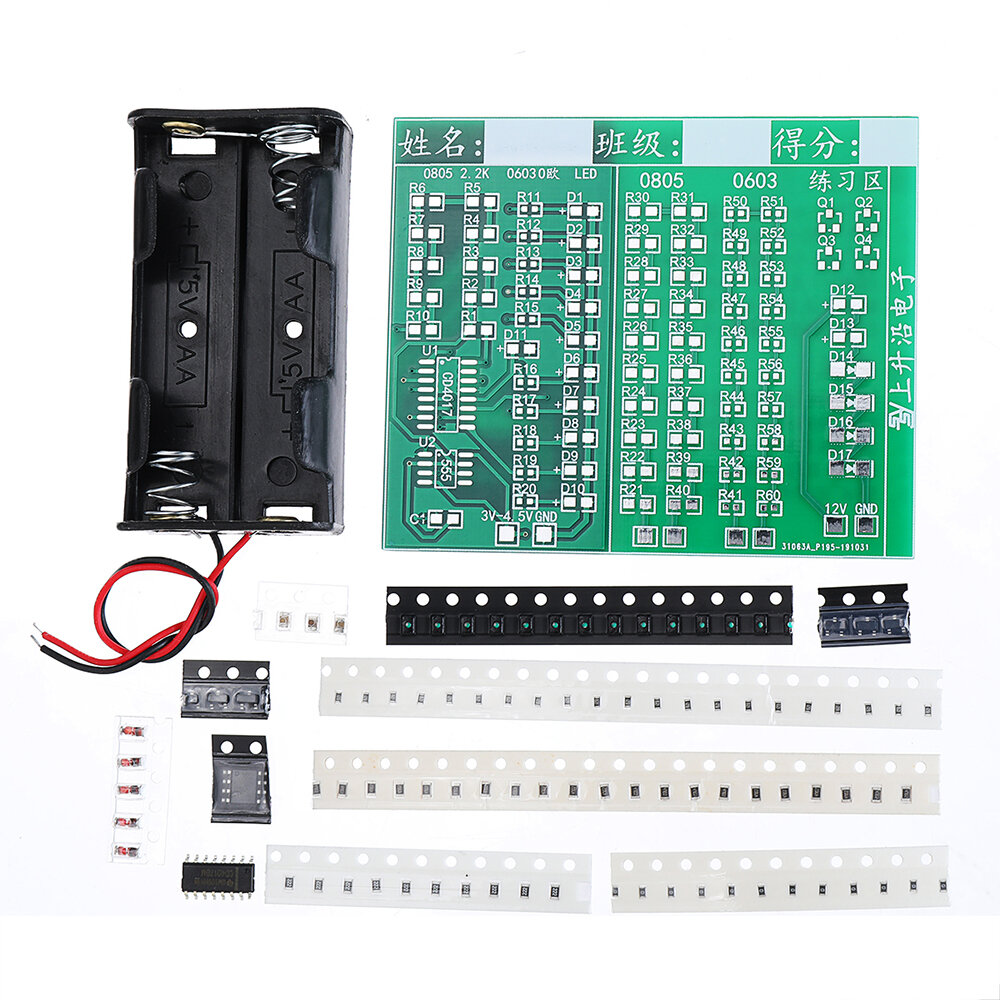

Package included:

300 x 0805 (2012) SMD White LED